If the plugin detects that current is 10.1A then an Estop will occur. For example, you could define a limit to 10A for the current.

Monitor one or more Vfd status variable (out frequency,current,speed,ac or dc voltage) by mapping them to user DRO.If the spindle stops (eg you press the stop button on the VFD), it causes an emergency stop in Mach3 disabled because of many noise problem.But on my RF45 or other machine whith a gearbox, spindle speed depends on the gear … But it is the speed of tool that interests us, not the motor …

Indeed, the first driver is specific to chinese spindle, the pulley system was useless. If we set the option, the calculation of the RPM will be done using ratio declared in Mach3. You just need to configure your VFD on the right way. Thus, the driver will be able to handle any kind of motor, not just those that run at 3000rpm 50hz.

Does not support the pulley system (RF45 has a 6 speed gearbox!).So after buying the RS485 adapter on ebay, after tests, tests and other tests, I found that the plugin worked, but not as I wanted. The ‘famous’ Huanyang VFD controller pluginĪnyone who wanted to control this chinese VFD began to use this plugin So As a specific driver was needed, i first looked over the net. The problem is that those VFD ar not fully compliant with the modbus protocol. Going further, I also chose to control the spindle with a Huanyang VFD.

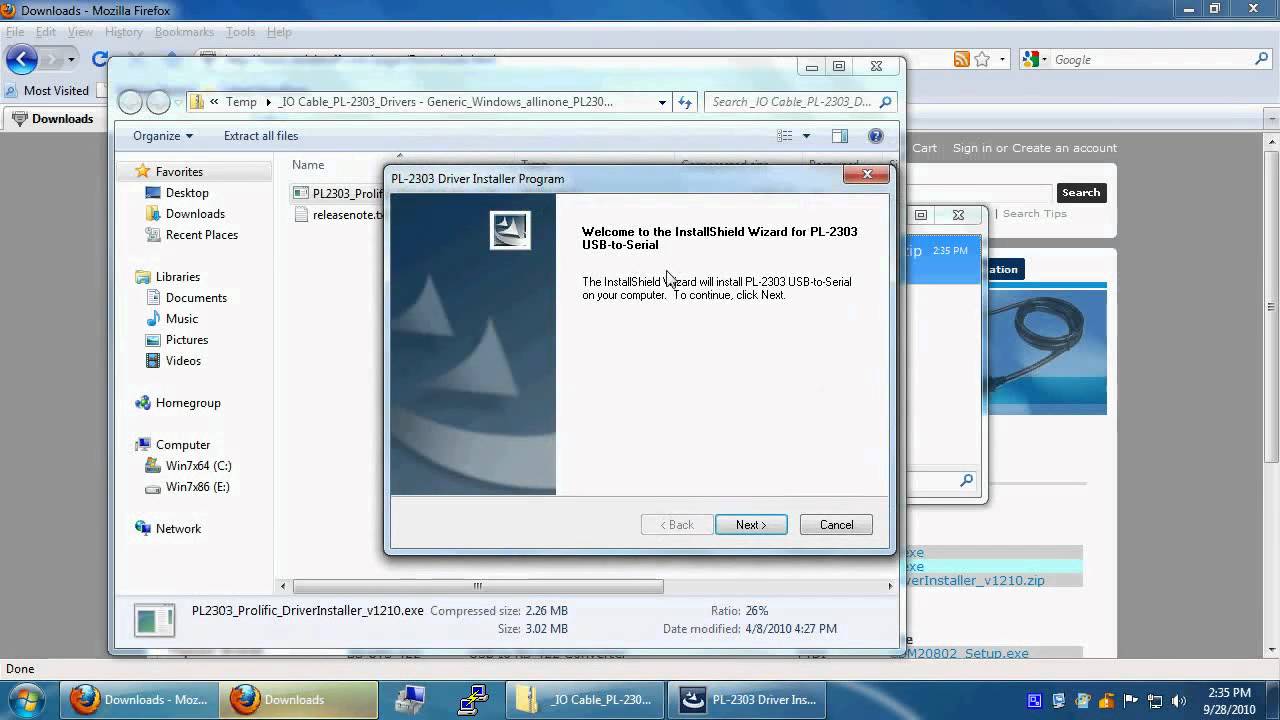

#Pl2303 prolific driver v1417 xp software

Mach3 software has been selected to control milling machine. If you uses the plugin, do not hesitate to donate! it will help me to pay web server and domain name to keep it free…many thanks.

0 kommentar(er)

0 kommentar(er)